Product Description

Product Description

HD469-251

FAQ

-

1. How long have you been in this business?

We have 17 years of industry experience. Mine truck parts only!

-

2.Do you have enough products?

10000 kinds of varieties. ONE STOP SHOPPING of mining Truck Parts.

-

3.Can you be trusted?

Our long-term good cooperation with 100+ customers around the world is the best proof.

-

4.Can there be an account period?

O/A 90 DAYS

-

5.Are you a factory or a trading company?

trading company. we have 2000+Factory perfect supply chain. Strictly check quality and control risk for you.

-

6.How long will the delivery?

Within a week.

-

7.Is there a discount for new customers?

New customers get up to 10% off their first order.

| After-sales Service: | on-Line Service |

|---|---|

| Condition: | New |

| Axle Number: | 3 |

| Application: | Truck |

| Certification: | DIN, ISO |

| Material: | Steel |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of vehicles or devices that use epicyclic gears?

Epicyclic gears, also known as planetary gears, are employed in various vehicles and devices for efficient power transmission and control. Here are some examples:

1. Automotive Transmissions:

Epicyclic gears are extensively used in automotive transmissions, including automatic transmissions and continuously variable transmissions (CVT). They allow for smooth gear shifting, gear reduction, and torque multiplication, enhancing vehicle performance and fuel efficiency.

2. Wind Turbines:

Many wind turbines utilize epicyclic gear systems to convert the low-speed rotation of the wind turbine blades into high-speed rotation required by the generator. Epicyclic gears enable efficient power transmission, allowing wind turbines to generate electricity effectively.

3. Robotics:

Epicyclic gears find applications in robotics for precise motion control and torque transmission. They are used in robotic arms, humanoid robots, and other robotic mechanisms where compactness and versatility are essential.

4. Industrial Machinery:

Various industrial machinery, such as conveyors, mixers, and machine tools, incorporate epicyclic gears for power transmission and speed control. Epicyclic gear systems provide reliable and efficient operation in demanding industrial environments.

5. Aircraft Systems:

Epicyclic gears are employed in aircraft systems, including helicopter transmissions and auxiliary power units (APUs). They enable gear reduction, torque multiplication, and precise control in critical aircraft operations.

6. Power Tools:

Many power tools, such as drills, grinders, and impact wrenches, utilize epicyclic gears to deliver high torque and variable speed control. Epicyclic gear systems enhance the performance and usability of power tools across various applications.

7. Bicycle Hubs:

Some advanced bicycle hubs employ epicyclic gears for gear shifting and multiple gear ratios. These gear systems allow cyclists to change gears smoothly, adapt to different terrains, and optimize pedaling efficiency.

8. Marine Propulsion Systems:

Epicyclic gears are utilized in marine propulsion systems, including marine transmissions and outboard motors. They enable efficient power transfer and speed control in marine vessels.

These are just a few examples of vehicles and devices that incorporate epicyclic gears. Their widespread use across various industries is a testament to the advantages and versatility offered by epicyclic gear systems.

How do epicyclic gears maintain smooth operation during gear shifts?

Epicyclic gears, also known as planetary gears, are designed to maintain smooth operation during gear shifts. Here’s a detailed explanation:

1. Overlapping Engagement:

During gear shifts, epicyclic gears often utilize overlapping engagement, which means that multiple gears are engaged simultaneously for a brief period. This overlapping engagement allows for a gradual transition of torque from one gear to another, reducing sudden shocks or impacts that can cause jerky movements or noise.

2. Synchronizers or Clutches:

In certain applications, synchronizers or clutches are used in conjunction with epicyclic gears to facilitate smooth gear shifts. Synchronizers help match the speeds of the gears being engaged, while clutches enable gradual engagement and disengagement of gears. These mechanisms ensure that the gear shifts are seamless and minimize any jolts or vibrations.

3. Controlled Torque Transfer:

Epicyclic gears allow for controlled torque transfer during gear shifts. By manipulating the arrangement of the gears, such as holding a specific gear stationary, the torque can be gradually transferred from one gear to another. This controlled torque transfer helps maintain smooth operation during gear shifts.

4. Proper Gear Design:

The design of epicyclic gears plays a crucial role in maintaining smooth operation during gear shifts. Factors such as gear tooth profile, backlash, and clearance are carefully considered to minimize any sudden changes in contact and minimize gear meshing noise. Well-designed gears ensure smooth and efficient power transmission during gear shifts.

5. Lubrication and Damping:

Effective lubrication of the gear system helps reduce friction and wear during gear shifts. It also aids in damping vibrations and noise generated during the shifting process. Proper lubrication and damping techniques ensure smooth operation and minimize any disturbances during gear shifts.

6. Precise Manufacturing and Assembly:

Precision manufacturing and assembly of epicyclic gears are essential for maintaining smooth operation during gear shifts. Accurate gear tooth profiles, tight manufacturing tolerances, and precise gear alignment help ensure proper gear meshing and minimize any irregularities that can cause jolts or noise during gear shifts.

In summary, epicyclic gears maintain smooth operation during gear shifts through overlapping engagement, the use of synchronizers or clutches, controlled torque transfer, proper gear design, lubrication and damping techniques, as well as precise manufacturing and assembly. These factors work together to ensure seamless gear shifting, minimize shocks or impacts, and provide a smooth and comfortable driving experience in various applications.

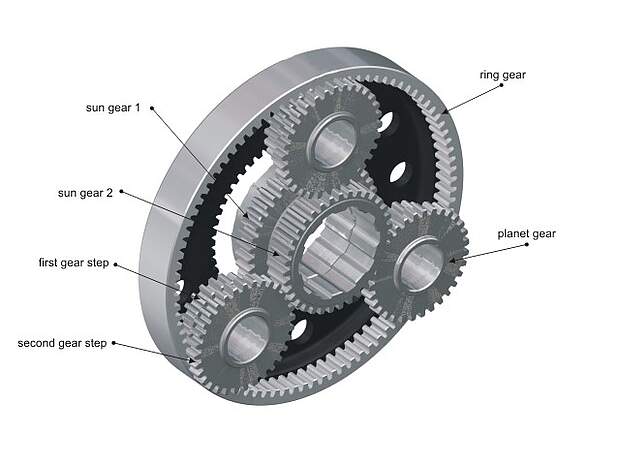

What is the role of a sun gear, planet gears, and ring gear in an epicyclic arrangement?

In an epicyclic gear arrangement, the sun gear, planet gears, and ring gear each have specific roles and functions. Here’s a detailed explanation:

1. Sun Gear:

The sun gear is the central gear component in an epicyclic arrangement. Its primary role is to provide the input rotational motion or power to the gear system. The sun gear is typically located at the center and is surrounded by the planet gears. It engages with the planet gears through meshing teeth, transmitting rotational force to them.

2. Planet Gears:

The planet gears are multiple gears that revolve around the sun gear in an epicyclic arrangement. They are mounted on a carrier, which holds and supports the planet gears. The planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it causes the planet gears to rotate around their own axes while simultaneously orbiting around the sun gear. The planet gears transmit the rotational motion and torque from the sun gear to the ring gear.

3. Ring Gear:

The ring gear, also known as the annular gear or the outer gear, is the outermost gear component in an epicyclic arrangement. It has internal teeth that mesh with the planet gears. The ring gear provides the outer boundary of the gear system and engages with the planet gears, transferring the rotational motion and torque from the planet gears to the output or the next stage of the gear system. In some arrangements, the ring gear is fixed or held stationary, while in others, it can rotate.

The combination and interaction of the sun gear, planet gears, and ring gear in an epicyclic arrangement enable various gear functions, such as gear reduction, torque multiplication, speed control, and directional changes. The arrangement and engagement of these gears determine the gear ratios and overall performance of the gear system.

editor by CX 2023-09-12