Product Description

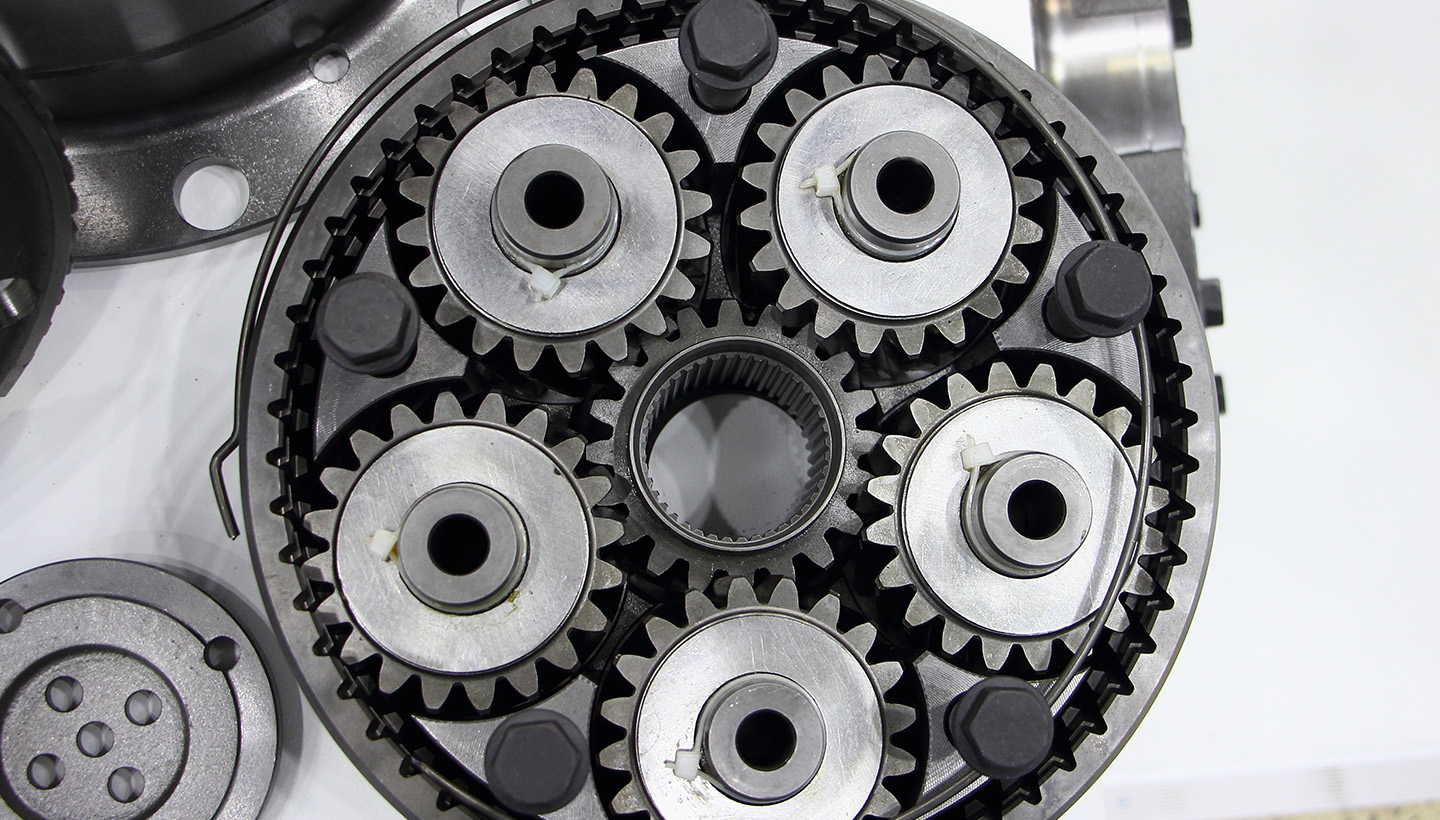

Customized Machining Tractor/Planet/Planetary/Epicyclic CHINAMFG Gear

Product Description

Major Products:

spur gear; worm gear; bevel gear; planetary gear; gear; metal gear; cycle gear; pinion gear; gear

manufacturing; helical gear; custom gear; spiral bevel gear; rack and pinion gear; mechanical

gears; transmission gears; rack gear; spiral gear; work gear; gear reducer; richmond gear;

hypoid gear; gear wheels; pulleys and gears; motive gear; gear teeth; truck gear; gear system;

involute gear.

|

Material |

Steel:Carbon steel/ Mild steel/ Cold roll steel/ Hot roll steel |

|

Surface Treatment |

Zinc plating, Powder, Passivation, Sand blasting, Brushing & ploshing etc. |

|

Processing Equipment |

Large laser cutter Bending machine Plasma cutting machine Punching machine Wire cutter CNC machining center CNC lathe Automatic lathe machine Milling machine Drilling machine |

|

Drawing Format |

pdf/.igs./.stp/x_t. etc. |

|

Drawing Format |

EXW, FOB, CIF |

|

Packing of Sheet Metal Stamping |

PE bag+carton box or other custom packaging |

|

Applications |

Auto Parts/Motocycle parts/Contruction Parts/Furniture Parts/Electronic Parts |

PRODUCT DESCRIPOTION

1. CHINAMFG wheel and pinion gears and spiral bevel gears for automobile rear axle, truck, tractor

front/rear axle and tool.

2. Raw material: 20CrMni \22CrMo \8620 \SCM420

Processing: Forging, normalizing, rough, machining, fine finishi, carburizing, tempering,

annealing, accurate grinding, matching and testing, packing.

3. The tooth surface is finished by lapping machine, the color will be silver gray

4. Hardness about surface: HRC58-62, internal: HRC35-40.

5. We can process gears according to customers drawing and samples.

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues,

Thread and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness

testers, etc.( Detection accuracy to 0.001 millimetre )

| Mininum of Quantity | 100 Piece/Pieces |

| Unit Weight | 0.5kg~300kg |

| Price | FOB HangZhou,China,USD1.5~1.9 |

| Packing Details | Paper Box in Wooden Pallet |

| Delivery Time | One month |

| Payment Terms | L/C, T/T |

| Machining | CNC or |

| Supply Capacity | 50 Metric Tons per Month |

| Standard | DIN,ASTM,GOST,B |

Packaging & Shipping

Packing:

1: Shrink film+ bulk loading

2: Shrink film +Carton box + Pallet/ wooden case

3: PP + Wooden case

4: As per customers’ requirements or negotiated

FAQ

Q1: How can I get cnc spare parts sample?

1. Sample fee will be free if we have in stock, you just need to pay the shipping cost is OK.

2. The sample of your own design needs to pay for the mold set up charge. Samples production takes

5-7 working days after set up charge received & size drawing approval.

Q2: How to pay for the order?

There are 4 options to pay the order: Bank Transfer; Western Union; Paypal; Payoneer. Kindly choose

the most suitable way for you to arrange it.

Q3: What is the shipping method?

The samples were sent out by international airway express company like DHL, UPS, FedEx, TNT.

Usually takes around 5-7 working days (door to door service). We arrange goods shipment via sea

or air.

Q4: Can you give me help if my products are very urgent?

Yes, We can work overtime and add a few machines to produce these products if you need it urgently.

Q5: I want to keep our design in secret, can we CHINAMFG NDA?

Sure, we will not display any customers’ design or show to other people, we can CHINAMFG NDA.

You can look through our website to find your interest or email your any questions through

below approach! We will reply to you within 12 hours.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 4/Piece

1 Piece(Min.Order) | Order Sample machining gears

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the benefits of using epicyclic gears in wind turbines?

Epicyclic gears, also known as planetary gears, offer several benefits when used in wind turbines. Here’s a detailed explanation:

1. Compact and Lightweight Design:

Epicyclic gears provide a compact and lightweight design for wind turbines. This is particularly advantageous in the nacelle, where space and weight constraints are critical. The compactness of epicyclic gears allows for more efficient use of available space and reduces the overall weight of the turbine, which simplifies transportation, installation, and maintenance processes.

2. High Power Density:

Epicyclic gears offer high power density, which means they can handle a significant amount of power transmission in a relatively small volume. This is particularly beneficial in wind turbines, where the generation of large amounts of power is required. The high power density of epicyclic gears allows for the efficient transfer of power from the rotor to the generator.

3. Load Distribution:

The arrangement of multiple planet gears in an epicyclic gear system helps distribute the load evenly across the gear teeth. This load distribution minimizes stress concentration on individual gear teeth, reducing the risk of premature wear or failure. In wind turbines, where the loads can be substantial, epicyclic gears contribute to improved durability and reliability.

4. Variable Speed Operation:

Epicyclic gears facilitate variable speed operation in wind turbines. By adjusting the gear ratio, the rotational speed of the generator can be optimized to match the varying wind conditions. This allows the turbine to operate at its peak efficiency, maximizing power generation and improving overall energy conversion.

5. Torque Limiting and Overload Protection:

The design of epicyclic gears allows for torque limiting and overload protection in wind turbines. By incorporating torque limiters or automatic shutdown mechanisms, excessive loads or sudden gusts of wind can be mitigated. This protects the gearbox and other components from damage and extends their operational lifespan.

6. Redundancy and Fault Tolerance:

Epicyclic gears can be configured in redundant arrangements, providing fault tolerance in wind turbines. By using multiple sets of gears, if one gear set fails, the remaining gears can continue to operate, ensuring the functionality of the turbine. This redundancy enhances the reliability and availability of the wind turbine, reducing downtime and maintenance costs.

Overall, the benefits of using epicyclic gears in wind turbines include compactness, high power density, load distribution, variable speed operation, torque limiting, and fault tolerance. These advantages contribute to the efficient and reliable operation of wind turbines, promoting renewable energy generation.

What are the challenges associated with designing and manufacturing epicyclic gears?

Designing and manufacturing epicyclic gears, also known as planetary gears, can present several challenges. Here’s a detailed explanation:

1. Complex Geometry:

Epicyclic gears have a complex geometry due to the arrangement of multiple gears and the interactions between the sun gear, planet gears, and ring gear. Designing the gear profiles and ensuring proper gear meshing requires advanced mathematical calculations and modeling techniques.

2. Gear Tooth Profile Design:

The design of the gear tooth profiles is critical to ensure smooth and efficient gear operation. Achieving the correct tooth profiles, such as involute or cycloidal, requires precise calculations and considerations for factors like tooth strength, backlash, and clearance.

3. Load Distribution and Gear Sizing:

Determining the appropriate number of planet gears and their sizing is crucial for achieving proper load distribution. The load distribution affects gear durability and performance. Designers must carefully analyze the load distribution and consider factors such as torque, speed, and material properties to ensure optimal gear sizing.

4. Manufacturing Tolerances:

Epicyclic gears have tight manufacturing tolerances due to their complex geometry and the need for precise gear meshing. Achieving the required tolerances during the manufacturing process can be challenging and may require specialized equipment and techniques.

5. Assembly and Alignment:

Proper assembly and alignment of the gear components are crucial for achieving smooth gear operation and minimizing wear. Aligning the gears with high accuracy during assembly can be challenging, especially in large gear systems where multiple components need to be precisely aligned.

6. Lubrication and Cooling:

Epicyclic gears require effective lubrication and cooling to ensure optimal performance and durability. Designing proper lubrication systems and ensuring effective cooling in the gear system can be challenging, especially in applications where gears operate under high loads and speeds.

7. Noise and Vibration:

Epicyclic gears can generate noise and vibrations during operation, which can be undesirable in certain applications. Designing gears that minimize noise and vibration requires careful consideration of factors such as gear tooth profiles, gear meshing, and damping techniques.

8. Cost and Complexity:

Designing and manufacturing epicyclic gears can be cost-intensive and complex compared to simpler gear systems. The complexity of the gear geometry, manufacturing tolerances, and assembly requirements can contribute to higher production costs and increased manufacturing challenges.

In summary, the challenges associated with designing and manufacturing epicyclic gears include complex geometry, gear tooth profile design, load distribution and gear sizing, manufacturing tolerances, assembly and alignment, lubrication and cooling, noise and vibration, as well as cost and complexity. Overcoming these challenges requires advanced design and manufacturing techniques, precision engineering, and careful consideration of various factors to ensure optimal gear performance and durability.

Can you explain the concept of planetary gear sets in epicyclic systems?

In epicyclic gear systems, planetary gear sets play a fundamental role. Here’s a detailed explanation of the concept:

1. Definition:

A planetary gear set consists of three main components: a central sun gear, multiple planet gears, and an outer ring gear, also known as the annular gear. The planet gears are typically mounted on a carrier, which allows them to rotate around the sun gear.

2. Gear Engagement:

The teeth of the planet gears mesh with both the sun gear and the annular gear. The sun gear is positioned at the center and is surrounded by the planet gears. The annular gear has internal teeth that engage with the planet gears, while its external teeth provide the outer boundary of the gear system.

3. Gear Motion:

The motion of a planetary gear set involves a combination of rotational and orbital motion. When the sun gear rotates, it causes the planet gears to rotate around their own axes while simultaneously orbiting around the sun gear.

4. Gear Ratios:

Planetary gear sets offer various gear ratios depending on how the components are held or driven. The gear ratio is determined by the number of teeth on the gears and the arrangement of the gear engagement. By fixing one component and driving another, different gear ratios can be achieved.

5. Gear Functions:

The arrangement and motion of planetary gear sets allow for a wide range of functions in epicyclic systems, including:

- Speed Reduction: By fixing the sun gear and rotating the carrier or annular gear, the output speed can be reduced compared to the input speed.

- Speed Increase: By fixing the carrier or annular gear and rotating the sun gear, the output speed can be increased compared to the input speed.

- Directional Changes: Changing the gear engagement arrangement allows reversing the direction of rotation between the input and output shafts.

- Torque Multiplication: The gear ratios in a planetary gear set enable torque multiplication, providing mechanical advantage between the input and output.

- Braking: By holding specific components, such as the sun gear or the carrier, the gear system can act as a brake, preventing rotation or controlling the speed of the output shaft.

Planetary gear sets are widely used in various applications, including automotive transmissions, gearboxes, power tools, and robotics. Their compact size, versatility in gear ratios, and ability to perform different functions make them essential components in many mechanical systems.

editor by CX 2023-11-06